• Oil & Gas,Pipeline Operators

• Oil & Gas,Pipeline Operators

(This is an abridged version of an article published in Gas Processing & LNG

on August 7, 2024.)

Pipeline leaks are a chronic problem that causes significant environmental damage. Government regulators, investors, insurers, and other stakeholders demand that oil and gas (O&G) producers better monitor pipelines for leaks that can harm the environment and the community. But, smaller leaks can be hard to detect, so major O&G companies are adopting geospatial analytics to pinpoint leaks before they become an environmental disaster.

A challenge all O&G producers face is monitoring a vast, aging pipeline infrastructure. These organizations manage thousands of miles of pipelines to deliver petroleum and natural gas. Early detection of pipeline issues is essential to minimize risk, reduce environmental impacts, avoid escalating costs, and eliminate the chances of public exposure to a leak.

The following are a few case studies on how O&G companies have utilized geospatial analytics for improved operations.

Created by O&G and pipeline companies, the Intelligent Pipeline Integrity Program (iPIPE) was founded to work with technology providers to adapt their technologies to meet the needs of pipeline operators. iPIPE’s goal was to eliminate the negative impact of pipeline leaks, with member organizations sharing the costs to deploy new technologies. iPIPE members included Hess Corp., Equinor, Oasis Petroleum, Goodnight Midstream, TC Energy, Energy Transfer, MPLx, ONEOK, Whiting Oil & Gas, and DCP Midstream, among others.

iPIPE completed real-world demonstration of Satelytics’ capabilities over four years in North Dakota and New Mexico. Using data captured from satellites and then processed for spectral analysis using AI, the results were delivered weekly to consortium members within hours of data capture, including the location and magnitude of liquid leaks. The initiative was a huge success, demonstrating to participating O&G producers and pipeline operators that this new technology could monitor pipelines and identify leaks before they became larger spills.

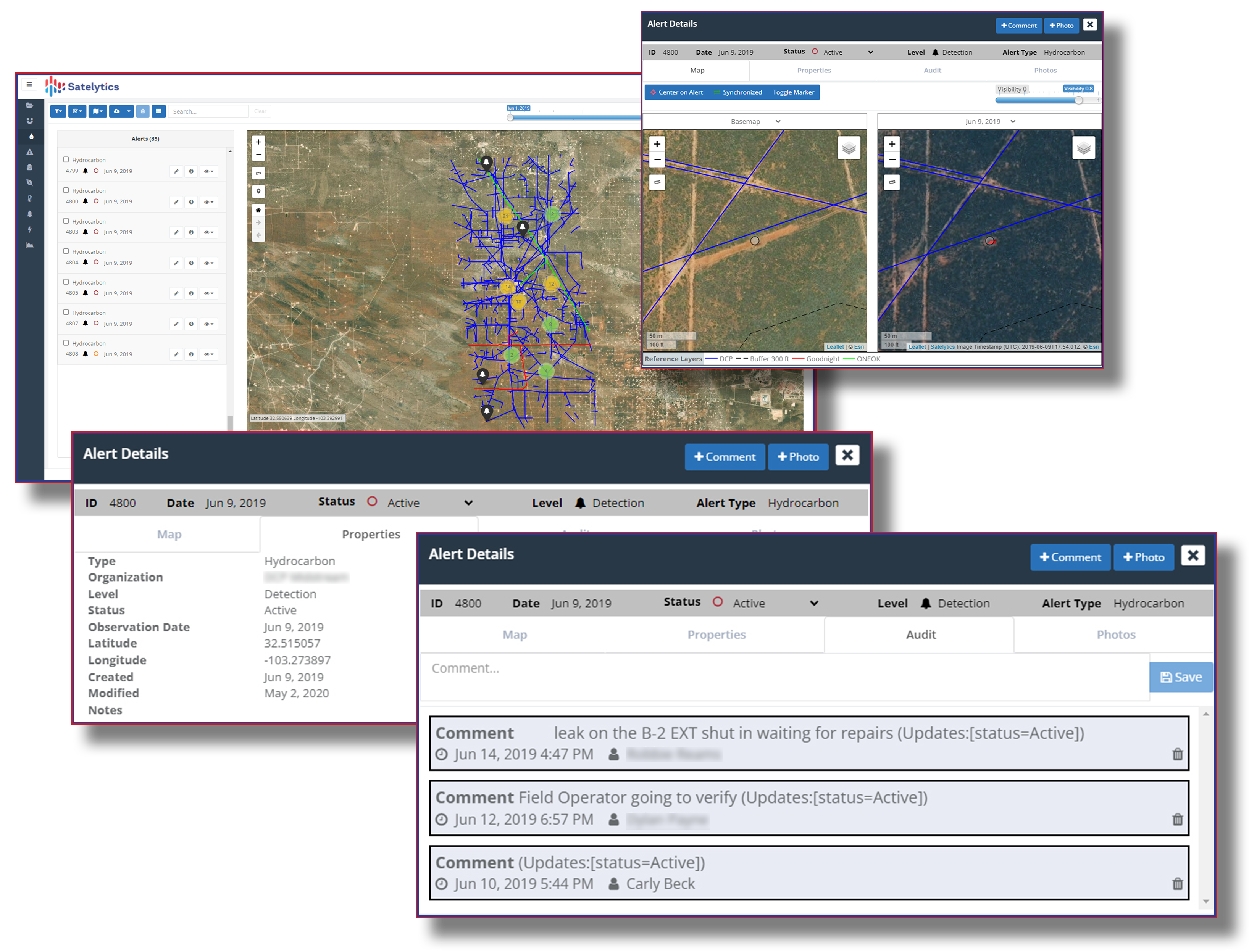

One of hundreds of pipeline leak alerts provided to iPIPE members.

The success of Satelytics’ work with iPIPE resulted in one of the founding members of iPIPE asking Satelytics to monitor the company’s entire fleet of assets in North Dakota, spread across nearly 10,000 km². Since 2021, numerous small pipeline and well site leaks have been identified long before the company believes it would have caught them via other means. In one specific instance, the customer said that the leak alert was provided 13 days before the company would have caught the leak via its traditional monitoring methods. This saved the company millions in cleanup costs, regulatory fines, and PR headaches.

The success of iPIPE and the incorporation of geospatial analytics into O&G producers’ normal operations piqued the interest of other producers who wondered if the same success could be realized everywhere. A new initiative is now underway to create a world-first collaborative industry-led effort to proactively monitor infrastructure basin-wide to ensure companies are simultaneously working in the best interest of the environment, the industry, and the shareholders. PermianSHIELD is a shared-cost program that would effectively monitor all O&G assets in the basin for liquid leaks, methane leaks, encroachment, and other risks while sharing the cost among all participating O&G companies.

North Slope water bodies have naturally occurring amounts of heavy metals, but well tailings leachate also contains similar metals. Another major O&G company wanted to determine whether metal concentrations in these water bodies were affected by production activities.

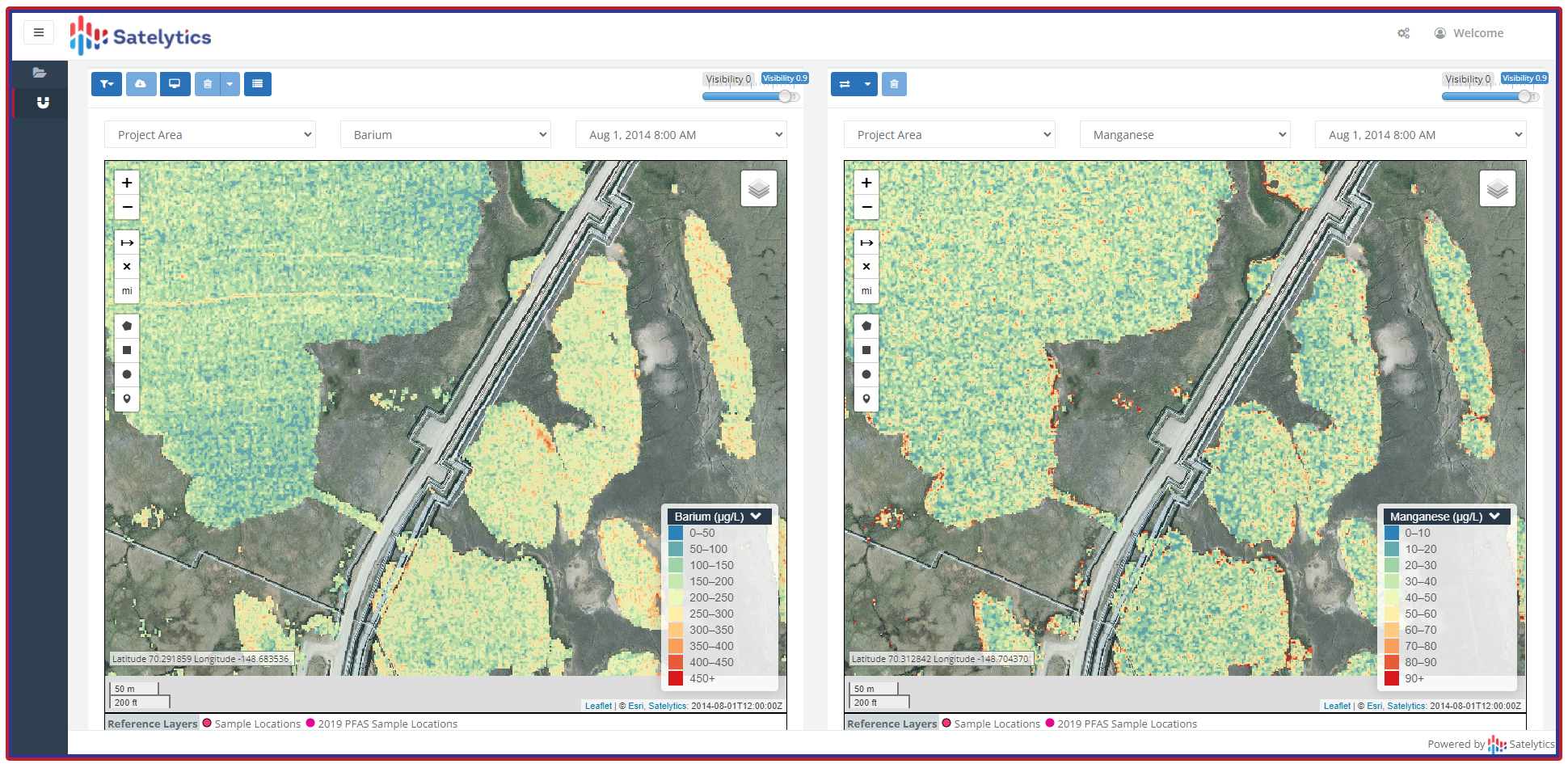

This O&G company leveraged Satelytics’ heavy metals algorithms to measure heavy metal concentrations on land and water. With customer input, Satelytics further refined its metal measurement algorithms and then calibrated them with robust ground-truthing. Together, we continued the measurement program for several seasons to gather data and fine-tune the algorithms for each metal. The results provided the O&G customer with proof that natural groundwater mechanisms, not tailings leachate, were causing the variations in metal concentrations in these lakes and ponds.

Measuring metal concentrations in North Slope water bodies.

Many O&G industry players now view AI-powered geospatial analytics as essential to reducing emissions and keeping communities safe. Finding any event in its infancy and locating the source and extent of the risks are all critical steps in avoiding or minimizing costly consequences, including loss of products or services.

Call us today to explore how oil & gas companies are harnessing geospatial analytics, benefiting their bottom line and the community.