• Agriculture,Forestry

• Agriculture,Forestry

The global palm oil industry stands at a pivotal crossroads. With Malaysia's 5.61 million hectares of oil palm plantations producing approximately 19 million metric tons of crude palm oil annually, the nation remains the world's second-largest producer of this essential commodity. Yet despite palm oil's theoretical yield potential of 17-18 tons per hectare, actual yields across Malaysia have stagnated at just 3-4 tons per hectare. This persistent yield gap represents billions of ringgit (hundreds of millions in USD) in unrealized revenue and underscores a fundamental truth: plantation operators cannot effectively manage what they cannot accurately measure.

Traditional methods of plantation monitoring rely heavily on manual sampling, periodic field inspections, and extrapolation from limited data points. A technician might walk select rows within a block, assess a fraction of trees, and use those observations to infer conditions across thousands of hectares. This approach, while time-tested, carries inherent limitations that compound over time.

Consider the scale of the challenge. A typical oil palm plantation contains between 120 and 150 palms per hectare, meaning a 10,000-hectare operation manages well over one million individual trees. Traditional manual counting methods require weeks of labor-intensive work, introduce human error, and deliver data that may already be outdated by the time decisions are made. Plantation managers often express frustration that even highly accurate measurements become obsolete by the time reports reach their desks months later.

The consequences of operating with incomplete information extend directly to the bottom line. Fertilizer costs alone represent 30-50% of total palm oil production costs, with field costs reaching RM 3,400-4,000 per hectare annually in Peninsular Malaysia. When plantation operators lack precise, tree-level data on nutrient requirements, they face an impossible choice: over-apply fertilizer and waste capital, or under-apply and sacrifice yield.

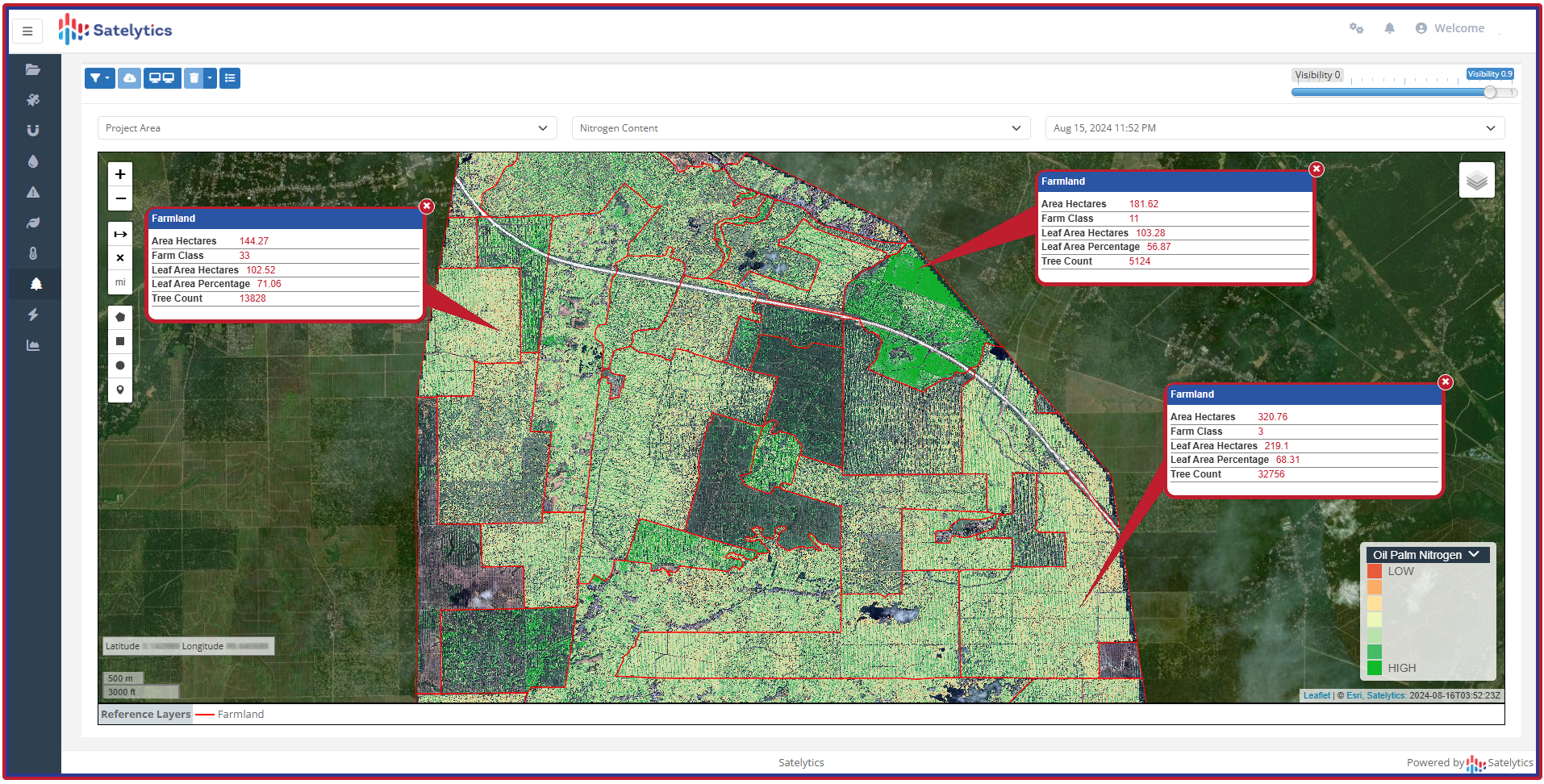

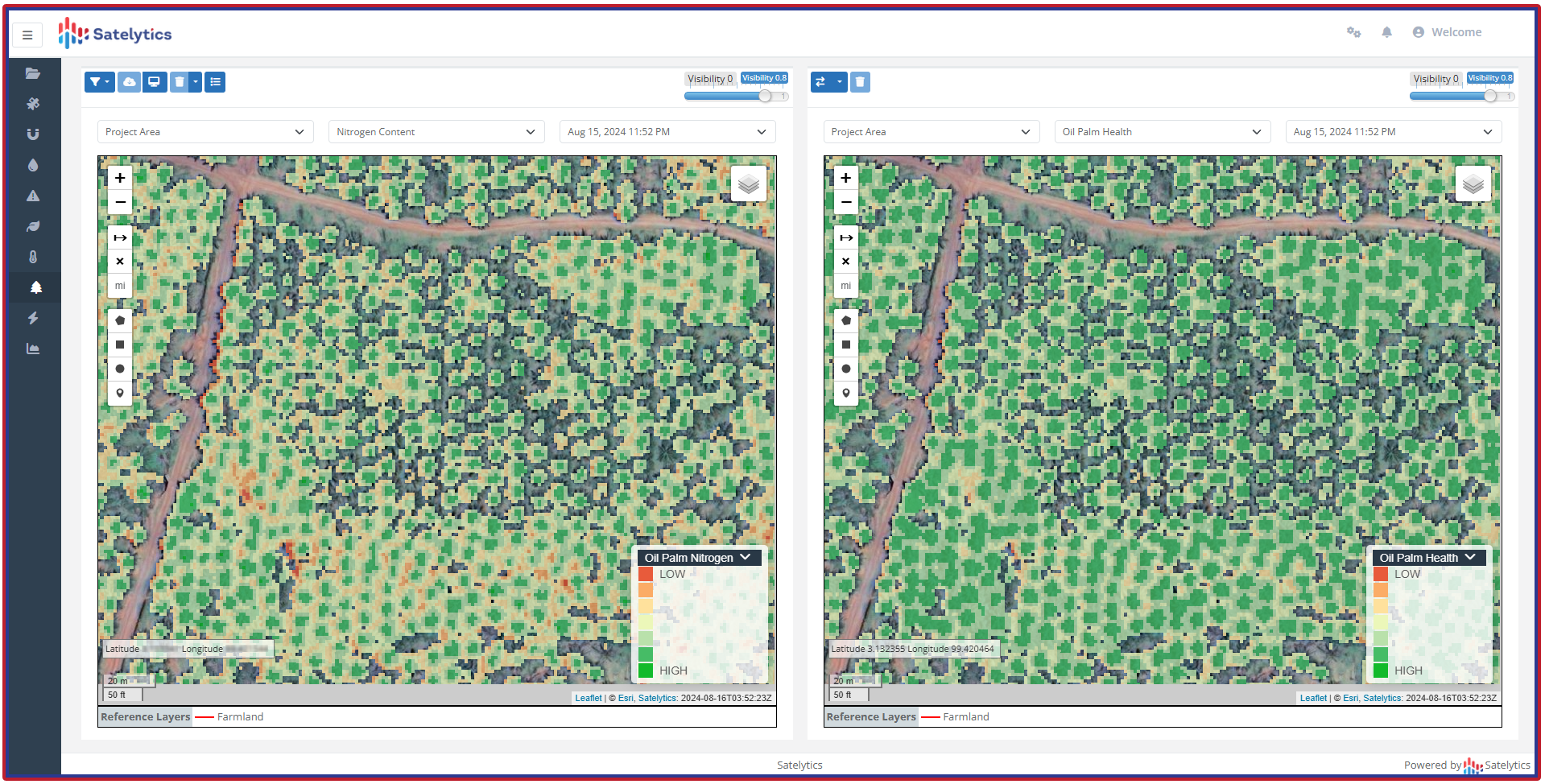

Satelytics, harnessing satellite imagery and AI-powered algorithms, is fundamentally reshaping how plantation operators approach this challenge. Rather than relying on spot checks and extrapolation, modern platforms analyze entire plantation footprints simultaneously, delivering quantitative results that transform vegetation management from guesswork into precision science.

Currently monitoring oil palm plantations in Malaysia, we combine multiple analytical capabilities, including tree counting, health assessment, height measurement, and nitrogen content analysis into a unified intelligence system that delivers actionable insights at a scale previously unimaginable.

Accurate tree counting forms the foundation of effective plantation management. Satelytics can detect and count individual oil palm trees with remarkable precision. This capability extends beyond simple enumeration. By maintaining precise inventories, plantation operators can identify missing or dead trees requiring replanting, track actual versus expected stand density, and calculate meaningful per-tree productivity metrics rather than relying on aggregate block-level averages.

Tree counts, tree density, tree health, and move over vast plantations.

Oil palm trees communicate their condition through subtle spectral signatures invisible to the naked eye but detectable through AI-based analysis of multispectral and hyperspectral imaging. Satelytics' vegetation algorithms leverage high-resolution imagery (typically 30-centimeter resolution, the size of a dinner plate) to identify symptoms of chlorosis and alert managers to compromised trees before problems become visible during routine field inspections.

This capability proves particularly valuable for early detection of Basal Stem Rot (BSR), the disease caused by Ganoderma boninense that represents the largest threat to Malaysia's oil palm industry. Traditional detection methods rely on visual inspection for symptoms like yellowing fronds, wilting, and fungal fruiting bodies on trunks. By the time these symptoms appear, infection has often progressed significantly. Satelytics can detect stress conditions earlier in the disease progression.

While LIDAR offers exceptional vertical precision, satellite-based approaches deliver tree height measurements within 5% of the actual value, which is sufficiently accurate for most operational decisions but offers dramatic advantages in coverage, frequency, and cost. More critically, this measurement capability supports assessment of individual tree maturity and productivity potential.

Oil palm follows a non-linear yield curve over its 25-year productive lifespan. Young palms produce little; mature palms (years 6-18) achieve peak productivity; aging palms decline. Height data, combined with historical planting records, enables operators to identify blocks approaching the end of their productive cycle and prioritize replanting decisions based on objective metrics rather than rough estimates.

Perhaps the most consequential capability for plantation economics is Satelytics' ability to measure nitrogen content directly in palm fronds. This represents a fundamental departure from traditional leaf sampling approaches, which typically involve collecting samples from a small subset of trees and extrapolating across entire blocks. Research demonstrates that fertilizing based on leaf analysis rather than blanket application rates can increase fresh fruit bunch yields by over 36% while achieving marginal rates of return exceeding 105%.

Frond nitrogen content... a measurement of need for fertilizer

The financial mathematics favoring a Satelytics monitoring program are compelling. Consider a 10,000-hectare plantation facing fertilizer costs representing 40% of production expenses. At current Malaysian field costs of approximately RM 3,400-4,000 per hectare, fertilizer represents RM 1,200-1,600 per hectare annually (RM 12-16 million across the entire operation).

Research indicates that precision agriculture techniques enable 20-30% reductions in fertilizer application while maintaining or improving yields. On a 10,000-hectare operation, this translates to potential savings of RM 2.4-4.8 million annually on fertilizer costs alone.

But savings represent only half the equation. Malaysia's palm oil industry experiences significant yield losses due to labor constraints, with an estimated 40,000-worker shortage affecting harvest completion. Even modest yield improvements of one ton per hectare across Malaysia's 5 million planted hectares could generate RM 5 billion in additional revenue.

Precision monitoring enables operators to prioritize the highest-value blocks for available labor, identify areas of stress requiring intervention before yields decline, and make data-driven decisions about replanting investments. The current industry replanting rate of just 2% annually (well below the 4-5% target needed to maintain productivity) reflects the difficulty of making these capital allocation decisions without reliable tree-level data.

Adopting Satelytics does not require massive infrastructure investment or fundamental operational restructuring. The practical implementation follows a straightforward pattern. Customers specify their areas of interest and desired monitoring frequency. Satelytics sources high-resolution imagery covering those areas and analyzes it using trained algorithms specifically designed for oil palm analysis. Results arrive as actionable alerts (specific problems, precise locations, quantified magnitudes) rather than raw data requiring extensive interpretation.

This approach offers another critical advantage: monitoring frequency matches operational needs rather than survey logistics. During critical periods (emergence from dry seasons, disease outbreak monitoring, pre-harvest assessment, et.al.), increased monitoring frequency provides the early warning that enables rapid response.

The trajectory of precision agriculture in oil palm cultivation points toward increasingly sophisticated capabilities. The integration of spectral analysis with AI-powered analytics continues to improve early disease detection, yield forecasting, and resource optimization. For plantation operators evaluating these technologies, several questions merit consideration:

The persistent yield gap between oil palm's theoretical potential and actual achievement represents not merely an agricultural challenge but an information challenge. Plantation operators managing millions of trees across thousands of hectares cannot manually gather the data required for truly optimized operations. They cannot sample their way to precision; they must measure comprehensively.

Satelytics bridges this gap by delivering quantitative, tree-level insights across entire plantation footprints. When operators know the exact count, precise location, current health status, height, and nitrogen uptake of every palm they manage, decisions about fertilizer application, labor allocation, disease response, and replanting become data-driven rather than intuition-based. Contact us to explore how Satelytics can help optimize your plantation operations.