• Mining & Extraction

• Mining & Extraction

Mining is an industry sector that fundamentally needs geospatial analytics to monitor its assets spread across vast geographies and in inaccessible locations. Mining operations currently occupy over 57,277 square kilometers worldwide, spanning more than 151 countries. Individual mine sites range from tiny operations to massive complexes like Chile's Salar de Atacama, spanning 1,354 km². Traditional ground-based monitoring methods cannot efficiently cover these immense footprints, particularly in remote wilderness areas far from existing infrastructure.

The economic stakes magnify this geographic challenge. Canadian mining companies control $352.6 billion in mining and mineral exploration assets, while the top 40 global mining companies generated $925 billion in revenue. Mining operations face severe risk exposure: tailings dam failures average $543 million per catastrophic event, and the national cost of cleaning up abandoned mine drainage in the United States ranges between $20 billion and $54 billion. In this high-stakes environment, comprehensive monitoring is existential.

Satellite-based, AI-powered monitoring delivers a transformative advantage: whole-area scanning at frequencies measured in days rather than weeks. Airbus’ Pleiades Neo and Vantor’s WorldView-3 satellites provide 30-centimeter resolution with daily global revisit cycles. This frequent revisit capability at high spatial resolution enables detection of small changes within days, rather than the weeks or months required for traditional field inspections. Daily satellite monitoring allows surface water accumulation to be tracked nearly continuously with weekly dashboard updates. When illegal mining activity occurs, high-resolution imagery identifies new excavation within days of activity starting.

Traditional monitoring operates on much slower schedules. Water quality sampling typically occurs monthly or quarterly under permit requirements, while major EPA-regulated facilities face inspections every two to three years. Small stream monitoring is often cadenced at just once every two weeks. Satellite monitoring eliminates these dangerous blind spots, scanning entire mine sites while field crews plan their next trip.

Tailings storage facilities represent a critical monitoring challenge. These massive earthen dams contain billions of tons of mining waste, often rising dozens of meters tall. Their failure consequences are catastrophic: 63% of tailings dam incidents since 1990 were classified as “serious” or “very serious”, with failure rates doubling from 8 incidents (1999-2003) to 16 incidents (2014-2018). The average financial impact reaches $543 million per major failure.

Advanced satellite techniques detect ground displacement without requiring equipment on the ground, eliminating installation and maintenance while providing near-continuous monitoring as dams are raised or expanded. Mining companies implementing satellite-based displacement monitoring report 30% cost reductions through decreased field inspection needs, while simultaneously lowering structural failure risk by 40% through early detection of ground movements. Data can be delivered hours after satellite acquisition, enabling rapid engineer response.

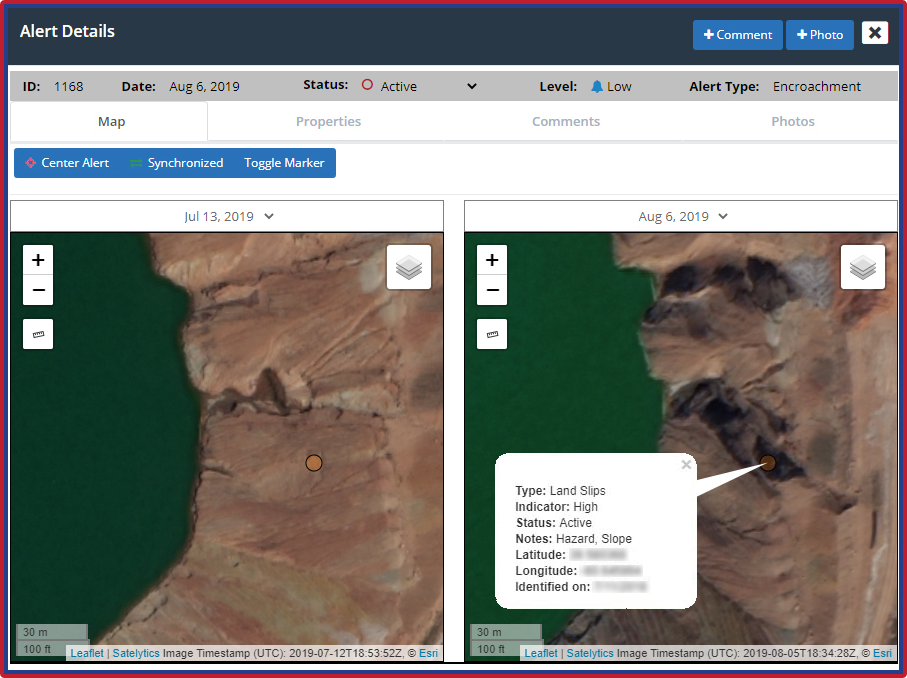

Movement in a tailings dam.

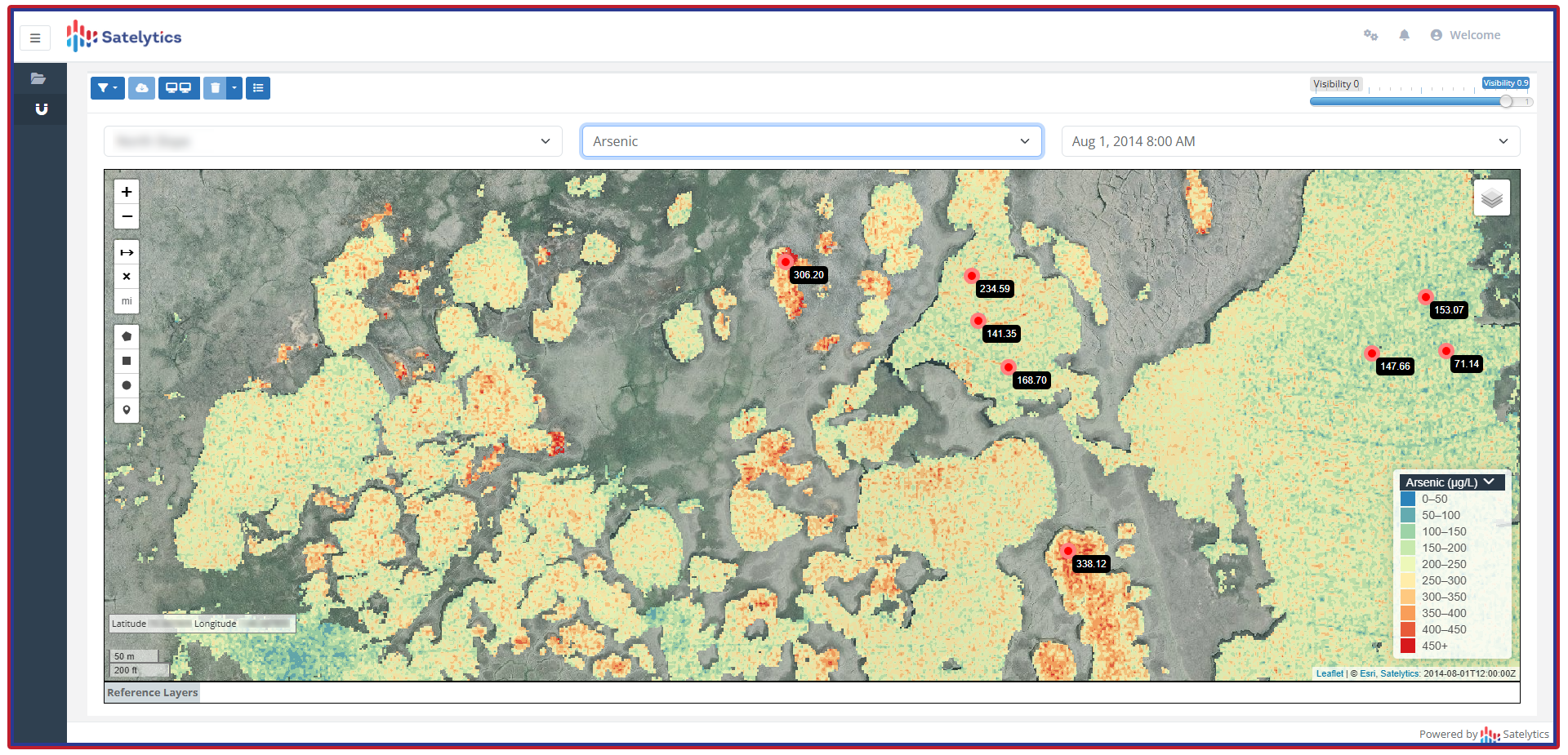

Mining operations generate complex water quality challenges across tailings ponds, acid mine drainage, surface runoff, and groundwater. Satellite-based monitoring tracks chemical and biological factors, including dissolved metals, suspended solids, turbidity, and chlorophyll-a, across entire water bodies simultaneously, extending the monitoring reach far beyond traditional point sampling.

Measuring arsenic in water bodies.

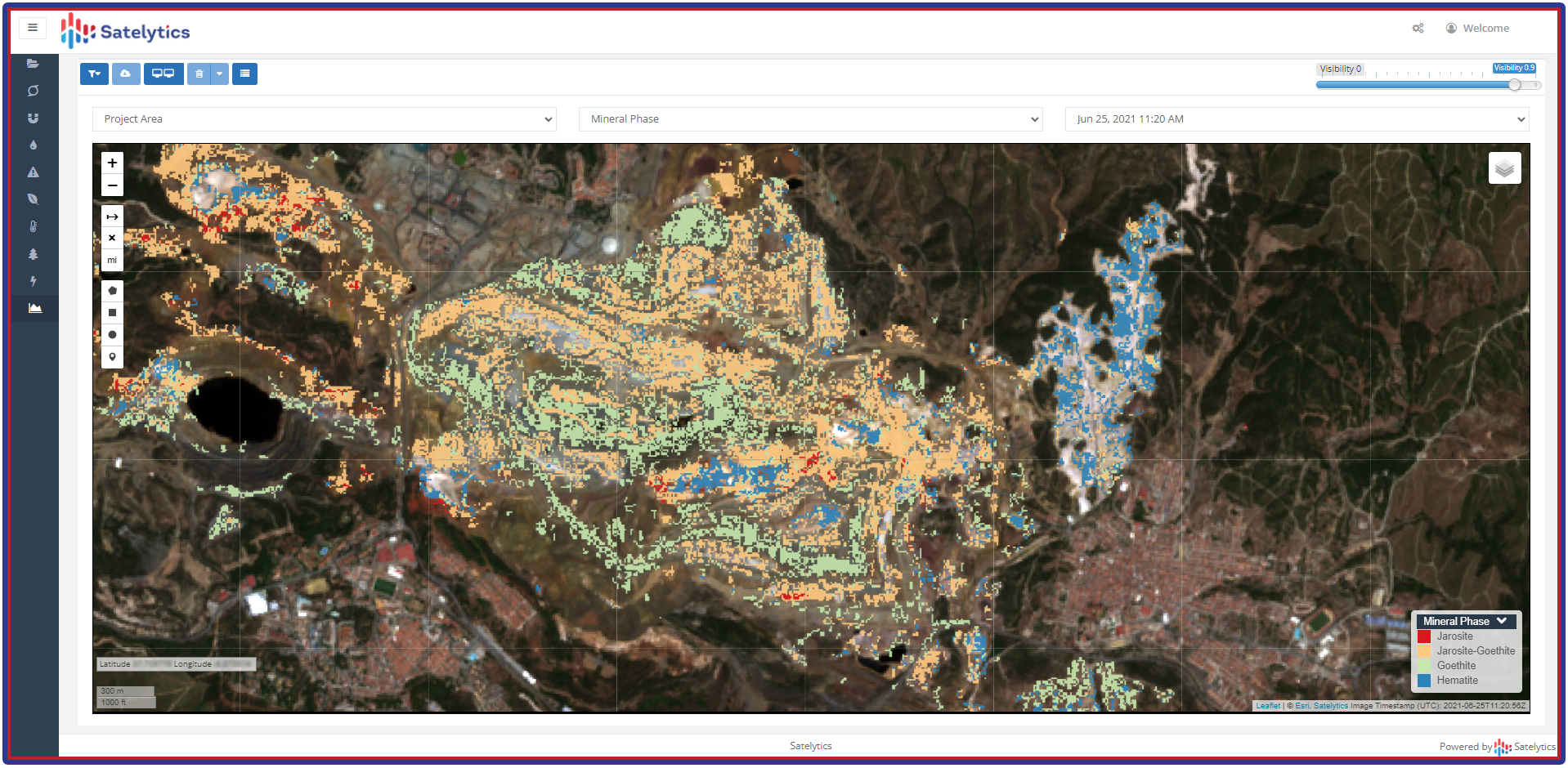

Different minerals reflect light at distinct wavelengths, creating unique spectral signatures that satellite sensors can identify. Mineral exploration has entered a new era through satellite-based analysis of chemistry indicative of subsurface mineralization. Advanced systems detect specific ores containing rare earth elements through diagnostic spectral features, providing cost-effective methods for screening Earth's surfaces for REE signatures critical to clean energy supply chains.

Satellite mineral mapping identifies alteration zones associated with gold, copper, and other metal deposits by detecting clay minerals and iron oxides. This approach reduces exploration costs, focuses drilling on the highest-probability targets, and shortens timelines from reconnaissance to resource definition.

AI-assisted mineral mapping.

Mine closure and reclamation demands multi-year data collection documenting vegetation establishment, erosion control, soil development, and water quality. Satellite remote sensing tracks these parameters efficiently across large rehabilitated footprints. Atlas Iron's Pilbara rehabilitation demonstrates the approach: annual vegetation and erosion monitoring tracked progress against 10-year completion criteria, with multiple rehabilitated areas achieving goals ahead of schedule.

Water erosion manifests across mining operations from surface sheet erosion to destructive gully formation, threatening slope stability, increasing sediment loads, and undermining reclamation. Satellite remote sensing detects erosion features through high-resolution optical imagery identifying gully networks, digital elevation models quantifying volumetric soil loss, and spectral indices tracking vegetation loss.

In open pit mines, satellite techniques detect ground movement before failure. Case studies from Nevada mines demonstrated satellite monitoring's predictive capability, detecting displacement anomalies weeks before collapse that traditional monitoring missed. Integrated monitoring programs combining satellite coverage with ground-based systems leverage their respective strengths: ground systems for real-time alerts in critical areas, and AI-powered analysis of satellite imagery for comprehensive coverage that detects displacement in unexpected locations.

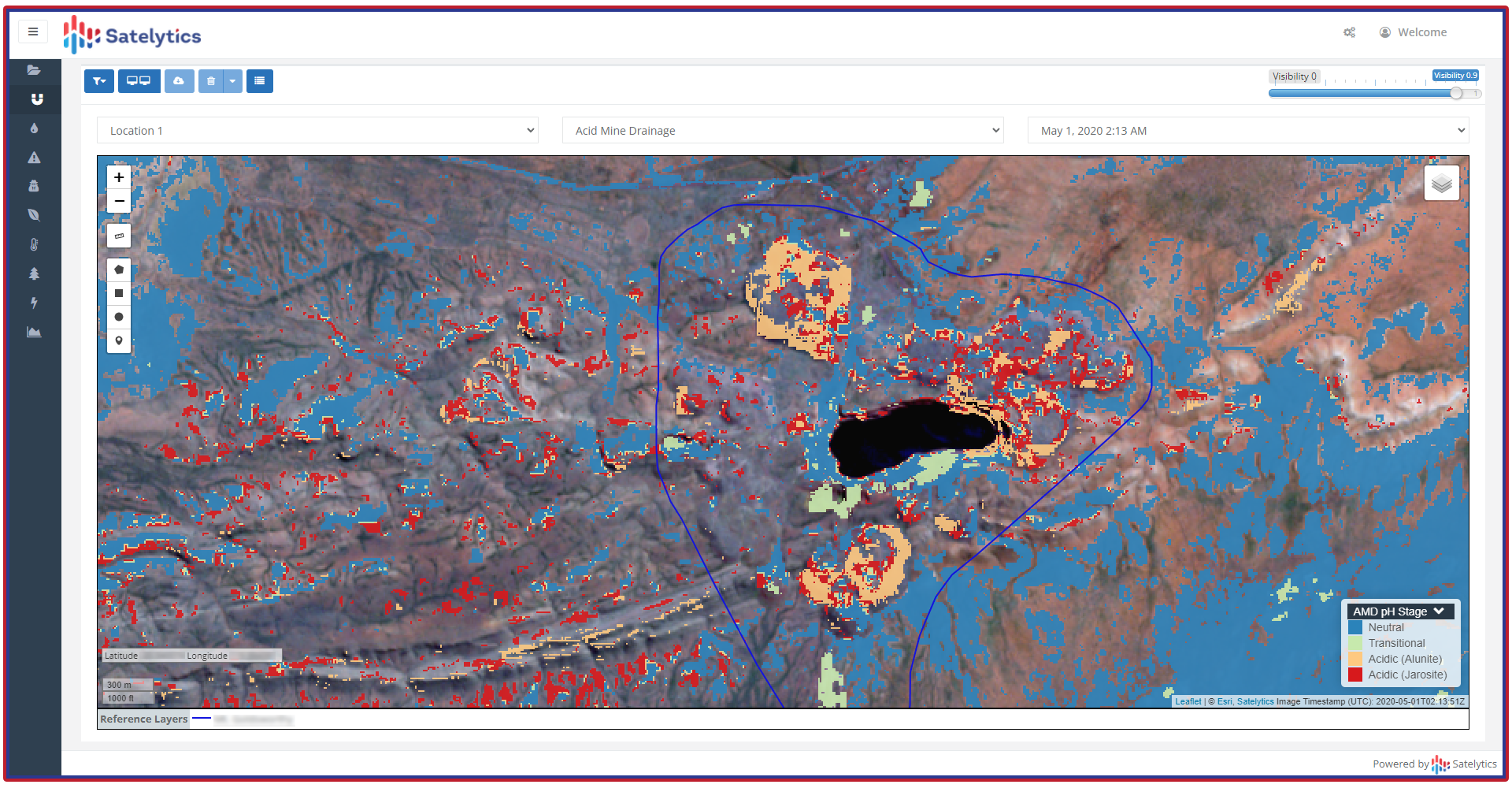

Acid mine drainage requires treatment for decades after mine closure, generating sulfuric acid and heavy metal contamination toxic to aquatic life. Treatment system performance monitoring traditionally relies on field sampling at inflow/outflow points. Satellite monitoring tracks treatment system conditions: water levels and chemistry in passive treatment ponds, vegetation health in constructed wetlands, and changes in effluent chemistry.

Acid mine drainage represents mining's most persistent environmental legacy, requiring treatment for decades after closure. Treatment systems cost $5,720 per kilometer annually to maintain, with Pennsylvania requiring $1.5 billion to treat 10,381 kilometers of affected streams. Southeastern Ohio invested $3.68 million in AMD remediation in 2023. Satellite monitoring cannot replace laboratory analysis, but it dramatically extends coverage and frequency, detecting pollution plumes and identifying contamination sources. Historical imagery archives dating back to 2009 provide baseline conditions and temporal trends that are impossible to obtain from point samples alone.

For operations managing multiple treatment sites across large areas, satellite monitoring enables prioritizing limited field resources toward locations with anomalies. Proactive maintenance prevents treatment failure, emergency response, and downstream impacts.

Monitoring AMD with AI-powered geospatial analytics.

Vegetation stress monitoring identifies environmental impacts and exploration targets by correlating spectral indices with soil moisture, nutrient availability, and chemical contamination. Illegal mining detection leverages change detection algorithms applied to high-frequency satellite imagery, identifying new excavations within days of activity beginning.

Modern mining operations cannot achieve operational excellence and regulatory compliance without comprehensive geospatial analytics. The industry faces too vast a geographic footprint and too severe a consequence profile to rely solely on traditional field inspections. Tailings dam failures average $543 million per incident, while national cleanup liabilities reach tens of billions of dollars, creating an economic imperative for monitoring systems that detect problems early and comprehensively.

Satelytics delivers this capability through advanced AI-powered algorithms that transform satellite data into actionable intelligence, including: tailings pond chemistry tracking dissolved metals, dam displacement monitoring, vegetation management evaluating reclamation success, and acid mine drainage proving environmental safeguards work.

Mining operations investing in geospatial analytics gain immediate advantages: reduced monitoring costs, improved risk management, enhanced regulatory compliance, and better stakeholder relations. Insurance carriers recognize these benefits, enabling premium reductions for operators demonstrating proactive risk management.

Contact Satelytics today to discover how our geospatial analytics platform transforms your mining operations from reactive monitoring to proactive management. Discuss use cases with our experts to develop a customized monitoring program that addresses your specific operational challenges. The future of mining monitoring is here… comprehensive, frequent, and essential.